COLLEGE CODE : MUT

Affiliated to APJ Abdul Kalam Technological University

Approved by AICTE

[email protected] | 0484-2883300/0484-2732100/111

Relentless passion for excellence...

(Promoted by The Muthoot Group)

COLLEGE CODE : MUT

Affiliated to APJ Abdul Kalam Technological University

Approved by AICTE

[email protected] | 0484-2883300/0484-2732100/111

Relentless passion for excellence...

(Promoted by The Muthoot Group)

Seventh Semester students of Dept. of Civil Engineering visited bridge construction sites of Mary Matha Infra Structure Pvt. Ltd projects on 17th October 2019. As part of their site visit, they have got an opportunity to witness the process of prestressing in bridges.

The S4, S6 and S8 students visited three construction sites of Aashiyana construction project at Kumarakom. S4 and S8 students visited the sites on 27-03-2019 accompanied by 3 faculty and 3 Lab Instructors. S6 students visited the sites on 29-03-2019, accompanied by 5 faculty and 2 Junior Engineers.

On 31th January 2019, students of S8 CE visited the Chambakkara Arch bridge construction site The site visit helped them to understand modern construction techniques adopted in the site. The visit was very interesting and enlightening for the students and faculty. The journey was under the leadership of Mr. Basil Mathai(Asst. Professor, Dept of CE).

The 2015 – 2019 batch of Civil Engineering students visited Idukki Dam on 5th January 2018.

Eighth semester Civil Engineering students, 2017-2018 batch went for a site visit to study Glass Fibre Reinforced Gypsum Board construction on 31 st January 2017.

A site visit by faculties of Civil Engineering Department to Muthoot Group Corporate Office site, Palarivattom on 13th January 2017.

ICI Student Chapter of MITS organised a site visit on 24th September 2019 for fifth semester students. Retaining wall and Box culvert sites under the Project of LSGD Puthencruz Panchayath were the sites of visit.

On 31st January 2019, students of S6 CE visited the Thykoodam Metro construction site. The site visit helped them to understand the modern construction techniques adopted in the site.The journey was under the leadership of Ms. Nishida A (Asst. Professor, Dept of CE) and Mr. Narayanan C R(Lab staff, CE).

As part of Industry-Interaction with Cochin International Airport Limited (CIAL), S8 Civil Engineering students of 2014-2018 batch attended one-day interactive programme on the working and conduct of Sewage Treatment Plant of CIAL. The classroom sessions of the programme were conducted at CIAL Academy. Students were accompanied by two faculties from the Department.

The students of 2013 – 2017 batch were visited Little Gems International School construction site, Infopark, Kochi, on13-2- 2017.

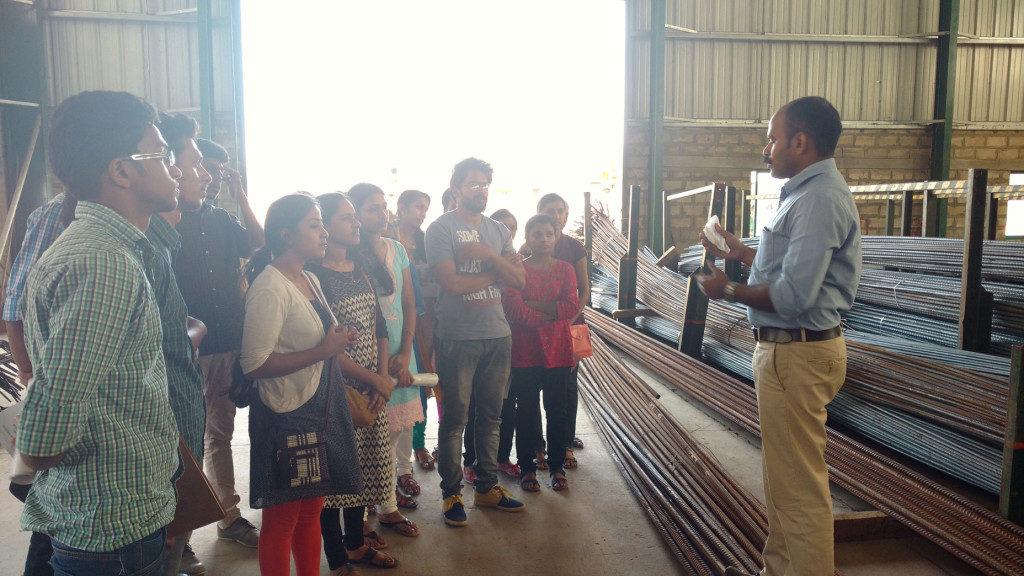

The students of Civil Engineering Department on their Beyond Classroom tours : their various field trips, study tours, in plant training.

On 30th January 2019, students of S4 CE visited the construction site of Muthoot Cooperate office Palarivattom. The site visit helped them to understand various construction methods used in the site. The journey was under the leadership of Mr. Sunith John David (Asst. Professor, Dept of CE) and Mr. Narayanan C R(Lab staff, CE).

| Sl. No. | Name of Industry | Number of Students |

|---|---|---|

| 1 | Madeckal Constructions | 9 |

| 2 | DH Academy | 1 |

| Sl. No. | Name of Industry | Number of Students |

|---|---|---|

| 1 | Cochin Shipyard Limited, Mahatma Gandhi Road, Revipuram | 6 |

| 2 | Geo Structurals (P) Ltd, Cochin | 1 |

| 3 | Kerala Public Work Department, Alappuzha | 1 |

| 4 | Marymatha constructions Muvattupuzha | 3 |

| 5 | Muthoot Housing and Infrastructure | 2 |

| 6 | Peter and sons company, Aluva | 1 |

| 7 | S F S Homes | 13 |

| 8 | Skyline Foundations & Structures Pvt. Ltd, Edappally | 10 |

| 9 | Suma Constructions (PUNE) | 1 |

| 10 | Zoom Builders and developers | 1 |

| Sl. No. | Name of Industry | Number of Students |

|---|---|---|

| 1 | Muthoot Housing & Infrastructure, Trivandrum | 11 |

| 2 | Cherian Varkey Construction Co. Pvt. Ltd., Kochi | 5 |

| 3 | Ahmadiah Contracting & Trading Co. | 1 |

| 4 | Aakkash Builders | 1 |

| 5 | Bin Nazar Developers | 5 |

| 6 | Dream Flower Housing Projects Pvt.Ltd | 7 |

| 7 | Homeland Built estate (P) Ltd | 12 |

| 8 | United Construction Company | 10 |

| 9 | Muthoot Housing & Infrastructure | 5 |

| 10 | Keltron, Thiruvananthapuram | 2 |

| 11 | Thiruvananthapuram Development Authority | 2 |

| 12 | P. W. D. NH Sub Division, Aluva | 5 |

| 13 | SFS Homes, Cochin | 3 |

| 14 | Stuba consultancy, Palarivattom | 6 |

| 15 | UST Global, Kochi | 1 |

| 16 | PWD-Mancherykuzhy bridge | 6 |

| 17 | Kerala State Nirmithi Kendra | 4 |

| 18 | Skyline, Palarivattom | 6 |

| Sl. No. | Name of Industry | Number of Students |

|---|---|---|

| 1 | J. P. ventures, Kochi | 4 |

| 2 | PVIP Sbu Division, Bhoothathankettu | 7 |

| 3 | Zone Builders, Kothamangalam | 5 |

| 4 | Asset Homes, Kochi | 2 |

| 5 | SFS Homes, Cochin | 1 |

| 6 | Cherian Varkey Construction Co. Pvt. Ltd, Kochi | 7 |

| 7 | NeST Infratech, Kochi | 4 |

| 8 | FACT, Kochi | 7 |

| 9 | Plan Arts, Kochi | 1 |

| 10 | Al Maizar Trad. Est., Salalah | 1 |

| 11 | PVIP Sub Division, Bhoothathankettu | 3 |

| 12 | Skyline Builders, Cochin | 6 |

| 13 | Sri. A.M.M.Murugappa Chettiyar Research Centre, Chennai | 4 |

| Sl. No. | Name of Industry | Number of Students |

|---|---|---|

| 1 | Verdant Homes Pvt. Ltd., Kochi | 5 |

| 2 | P. X. Foundation, Kochi | 6 |

| 3 | PVIP Sub Division, Muvattupuzha | 1 |

| 4 | FACT, Kochi | 1 |

| 5 | United Metals, Muvattupuzha | 8 |

| 6 | P. X. Foundation, Kochi | 6 |

| 7 | V. K. J. & Company, Kothamangalam | 7 |

| 8 | Aashrami Consultancy & Technology Pvt. Ltd., Kochi | 1 |

| 9 | Jyothy Constructions, Aluva | 1 |

| 10 | Cherian Varkey Construction Company | 6 |

| 11 | RightEdge Infrastructures Pvt. Ltd | 3 |

| 12 | Kannur International Airport Ltd. | 3 |

| 13 | FACT Ltd. | 5 |

| 14 | Crescent Contractors Pvt. Ltd. | 3 |

| 15 | Kerala State Coastal Area Development Corporation Ltd. | 5 |

| 16 | Cochin Port Trust | 6 |

| 17 | Cochin Shipyard Ltd. | 4 |

| 18 | The Uralungal Labour Contract Co-operative Society Ltd. | 2 |

| 19 | Nagarjuna Construction Company Ltd. | 9 |

| 20 | Marymatha Construction Company | 5 |

| 21 | Kerala State Coastal Area Development Corporation Ltd. | 1 |

| 22 | SFS Homes | 2 |

| 23 | Kerala PWD Roads & Bridges Division | 2 |

| 24 | GCK Associates | 1 |

| Sl. No. | Name of Industry | Number of Students |

|---|---|---|

| 1 | Delhi Metro Rail Corporation Ltd. | 6 |

| 2 | Cherian Varkey Construction Company | 8 |

| 3 | FACT Ltd. | 5 |

| 4 | INDUS Motors | 4 |

| 5 | Cochin Shipyard Ltd. | 4 |

| 6 | SFS Homes | 9 |